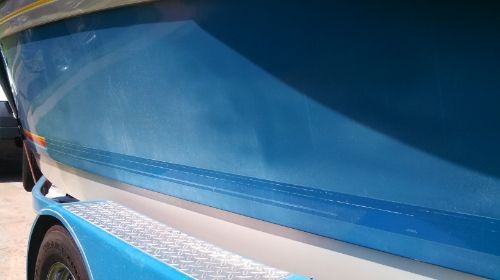

It seems like the 400 with the sander over the bulk of the area is just a quick pass and the oxidation is off. I'm paying attention to the color of the water, mostly. I can see the water change from white to blue. Down where the stripe was is where my biggest problem is. I'm still seeing a lot of discoloration and very distinctly seeing the difference between where the stripe was and the surface that has been exposed. I'm trying to tone that down as much as I can.

Reply With Quote

Reply With Quote