Well I am back for more wisdom, trying to bring back the shine to my old supra. I removed the cover snaps in the fiberglass and 90% of them have spider cracks and at least 10 of them have chunks out of the gell coat.

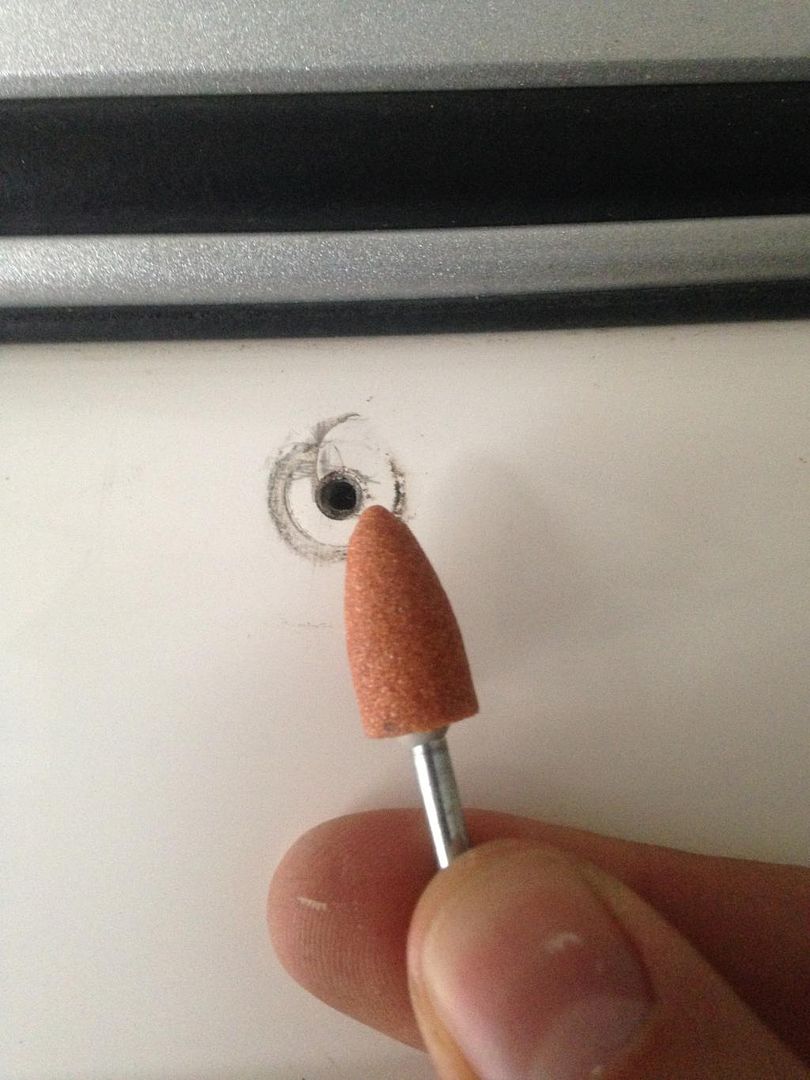

It doesn't appear that who ever installed the snaps chamfered the holes and that is what is causing the spider cracks. IDIOTS!!!! so now I need to deal with this problem before it gets worse. As Mr. Hunter has said: Quick Fluff & Buff Has Gone Awry! but not quite to his level.The plate that obscures the hole for tower lighting was drilled correctly, which makes me think that the snap cover wasn't factory installed.

Think I could use that in a low speed drill going counter clockwise to not catch the start of chip that is already there? In my line of work when we have cracks in steel we drill the end of the crack so it doesn't continue, could I do the same to the layer of the jell-coat? What about sealing up everything? Would some 4200 work? Thanks in adv guys!

BOWZ

Reply With Quote

Reply With Quote