Fman - thanks for the great write-up, I've got my account setup with wakemakers and am filling the cart for the order.

A couple things got me thinking, both regarding venting the bags

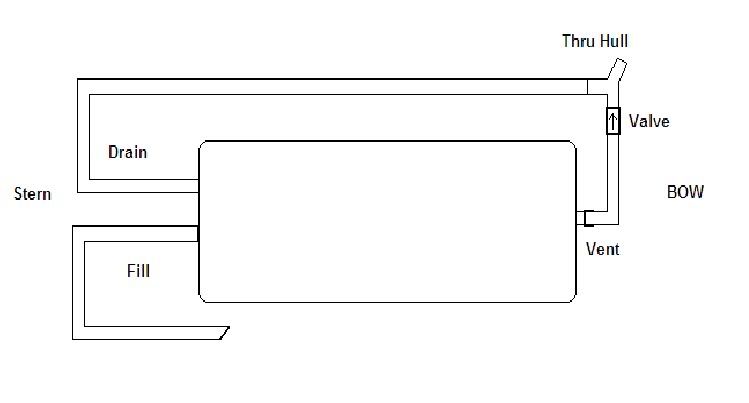

1. I wonder if all three bags could be tied in to one check valve/vent line. It seems like it could work since it's just air getting pushed out, although, what would keep the bags from venting in to one another. And for that matter, if a bag over fills and tries to push water out the vent line it may just end up filling another bag. Suppose I just talked my way right through that thought..... thanks for listening

2. If the bag is being vented, is there still a need for the anti-siphon loop on the fill side? The anti-siphon valve is basically there to create an air gap in the system so water won't be pushed/pulled in to a closed system. So, in essence, couldn't the "air gap" be located anywhere on the system? ie: bag vent located above draft line? Although, the anti-siphon loop helps prevent back-draining of the bag.

Certainly not trying to reinvent the wheel here, just some random thoughts I had.

Here's what I've got in my cart,

Attwood Tsunami 800 GPH Ballast Pump (x3)

Fly High Tsunami 800 / 3/4" Hose Barb Adapater W745 (x3)

3/4" Vented Loop Anti-siphon Valve (x3)

3/4" Non-Return Check Valve Fitting (x3)

3/4" Hose Barb Tee Fitting (x3)

Fly High 3/4" Straight Flow-Rite Quick Release Connector W740 (x3)

Fly High 3/4" Flow-Rite Quick Release Connect W736 (x3)

Last summer we found ballast hose at ACE Hardware, and everything else for the manifold can be sourced at Home Depot? Thanks again

Reply With Quote

Reply With Quote