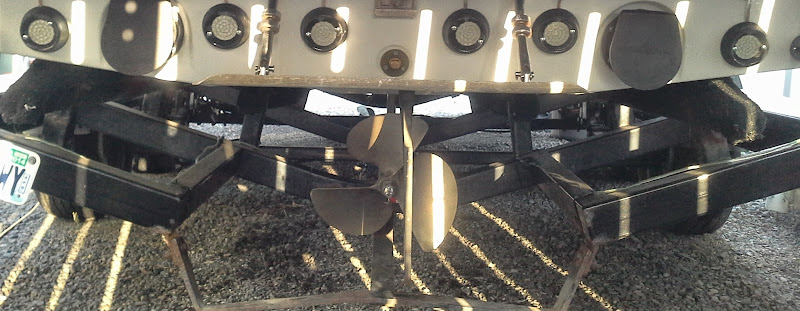

So, I had chose to drill my holes above the lights because I wanted the lights as LOW on the hull as possible and didn't want to risk not being able to access the wires. So the holes for the wires are all above the stringer level. As you can see from this pic, the wires go through the hull just above the stringers and had I tried to mount the lights where I did, I wouldn't have been able to access their wiring from the back...

I was actually really suprised that the hull was barely thicker than 1/4 inch. It was probably 5/16th's of an inch at most. That meant that I was going to have to patch holes for not only the wires, but also for the screws...

Sadly, it didn't turn out as nice as I'd like with the wires going through the hull and the 3m 5200. I've got some ideas for how I'll clean up that, so in the meantime you only get to see the mounted lights, not my "unfinished" section where the wires go through the hull.

I was thinking that 4 lights would probably be "good enough". So I did 6 because anything worth doing is worth over-doing!!!

Last night I ran the wiring to power and ground. I made sure to test to polarity of each one. I had an unused factory switch on my dash that was labeled "aux" so I used it for the lights. So, now my factory court light switch is for my interior LED's. My factory Aux light switch controls my tower mounted spot lights. And the factory Aux switch is the transom LED's. I'm pretty happy with how that worked out.

This shot is taken from an angle obviously. I think they're going to look pretty cool underwater.

If I had to do this over again, I would drill my holes for the wire in the center of the plastic housings. I then would make a way to keep the housings level as I poured the epoxy in them. (maybe a piece of cardboard with holes in it? Or a board with holes drilled it it?) I would then choose my locations for the lights and drill from the inside of the boat to the outside. that way I could be sure I could get them mounted low without worrying about the stringers keeping me from the back of the wires. I would then most certainly mount the lights over the hole so neither the hole nor wire could be seen. I made a judgement call by thinking I could have the holes higher and the lights lower and while functional, it's not as asthetically pleasing. And man, that 3m 5200 is messy crap to work with.

But in the end, I have some bright, waterproof lights that will look awesome while underway for less than I'd pay to purchase some.

Reply With Quote

Reply With Quote